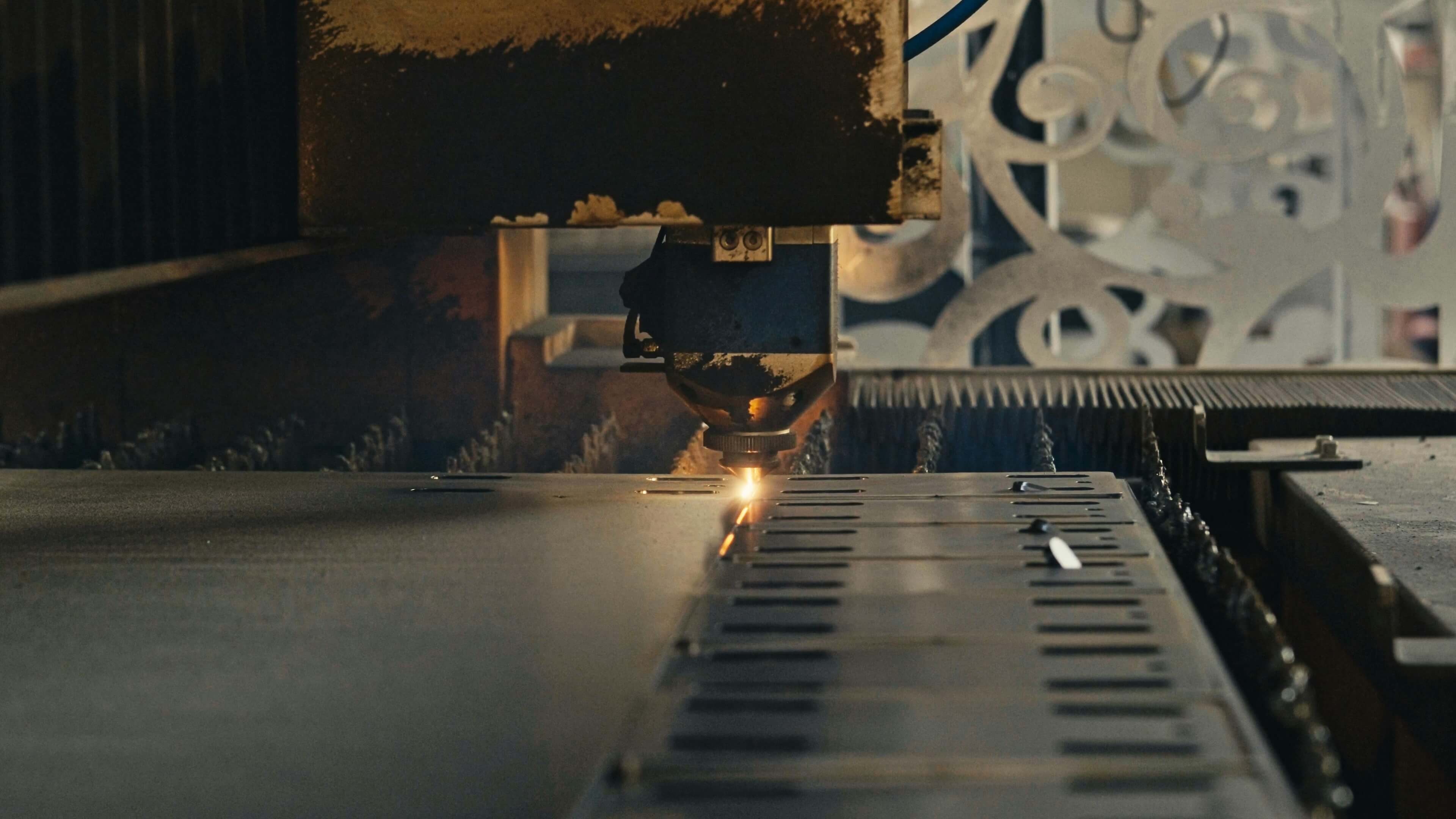

State-of-the-Art Manufacturing

Advanced technology meets traditional craftsmanship

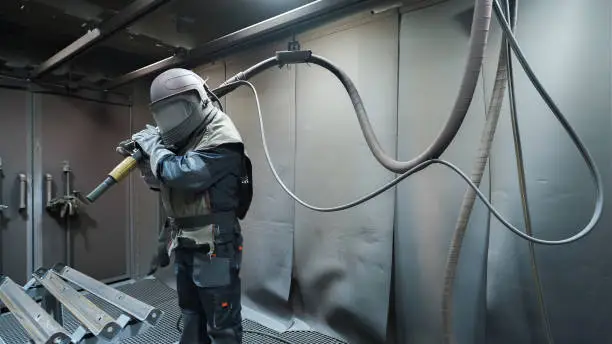

At Devkisteel Maishamabati, we combine modern manufacturing technology with skilled craftsmanship to produce high-quality steel products. Our facility in Nairobi's Industrial Area is equipped with the latest machinery and staffed by experienced artisans.

We maintain strict quality control at every stage of production, ensuring that every door, window, gate, and roofing sheet meets our high standards of durability and finish.

10+ Years

Manufacturing Experience

5000+

Products Made Monthly

100%

Quality Assurance